Scalemail armor offers a stunning mix of artistry and protection, reminiscent of ancient warriors adorned in gleaming scales. With the advent of 3D printing, crafting this unique armor has never been more accessible or exciting.

In this guide, we’ll walk you through the process of creating your very own 3D printed scalemail shark, blending creativity with cutting-edge technology that is transforming the realms of crafting and cosplay.

Whether you’re an experienced maker or a curious newbie, this project promises to be rewarding and fun!

Table of Contents

ToggleWhat is a 3D Printed Scalemail Shark?

Definition

Scalemail is a type of armor formed from many overlapping plates, offering both flexibility and protection. Unlike traditional metal armor, 3D printed scalemail combines both aesthetics and advanced printing technologies for a lightweight alternative, perfect for costumes and reenactments.

Overview

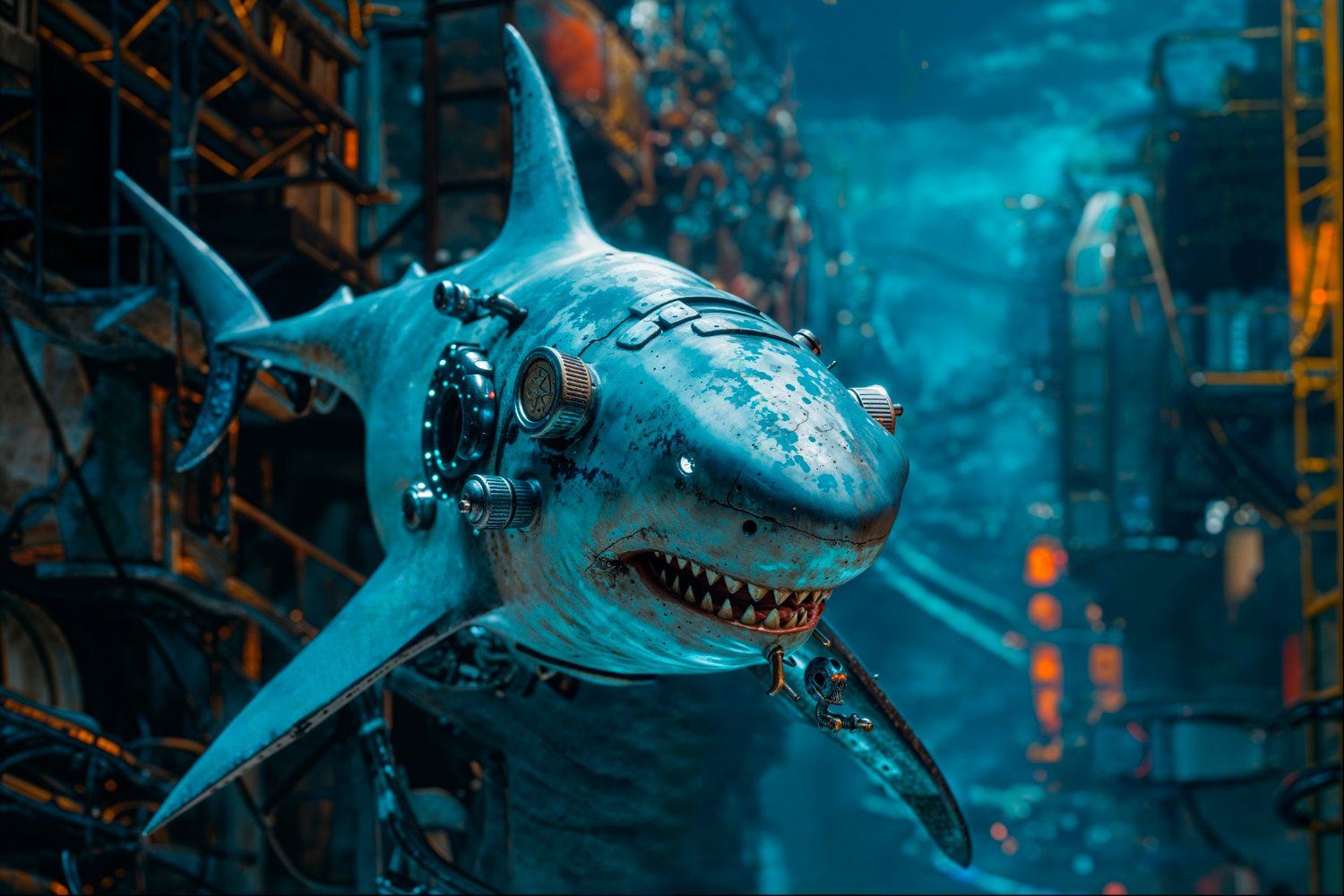

Our design features a majestic shark motif, making it not only a piece of armor but also an eye-catching representation of power and agility. The artistic design can be tailored to suit your personal style, either highlighting your love for marine life or adding a fierce edge to your cosplay outfit.

Why Choose 3D Printing for Scalemail?

Advantages of 3D Printing

- Precision in Design and Detail: 3D printing allows for intricate designs that traditional methods may not easily replicate.

- Customization Options: You can adjust size, colour, and style to create a unique piece that fits your vision.

- Reduced Material Waste: 3D printing utilizes only the necessary materials, ensuring a more efficient crafting process.

Materials Needed

To embark on your 3D printed scalemail shark project, assemble the following materials:

- 3D Printer and Filament: Opt for a FDM printer with PLA or PETG filament for the best results.

- Design Software: Popular options include TinkerCAD or Fusion 360, which are user-friendly for all skill levels.

- Assembly Tools: Scissors, glue, and a heat gun may be necessary for post-processing and assembly.

Step-by-Step Process to Make a 3D Print Scalemail Shark

Step 1: Design Your Shark Scales

Using Design Software: Begin by sketching out your shark scale model. There are many online resources to download pre-made designs or you can create one from scratch, tailoring it to your desired aesthetics.

Step 2: Preparing the Printer

Settings and Calibration: Ensure your printer is adequately calibrated to guarantee high-quality prints. Adjust settings for layer height, print speed, and temperature to suit your filament type.

Step 3: Printing Your Shark Scales

Print Time: Depending on the size of your design, printing can take several hours. For efficiency, consider batch printing multiple scales at once.

Step 4: Post-Processing

Cleaning the Prints: Carefully remove any support structures and smooth rough edges using sandpaper or a file.

- Painting and Finishing Options: Enhance your scales with paints or finishes that bring out depth and a lifelike quality. Metallic finishes can amplify the armor-like appearance.

Step 5: Assembly

Assembling the Scalemail: Connect the scales using rings or cords, ensuring they are securely fastened. This method maintains flexibility while allowing for a solid fit.

Conclusion

Creating a 3D printed scalemail shark is both a thrilling and fulfilling project that merges artistry with innovative crafting methods. This guide has equipped you with the essential steps to turn your imaginative concept into a reality.

Dive into this adventure whether for cosplay, display, or simply for the joy of making. Nothing compares to the satisfaction derived from crafting something uniquely yours!

FAQs

How Durable is 3D Printed Scalemail?

The durability of 3D printed materials generally holds up well under typical wear; however, it’s essential to consider the filament type and thickness of the print. PLA is great for looks, while PETG offers more flexibility and strength.

Can I Make Custom Sizes?

Absolutely! One of the key benefits of 3D printing is the ability to modify designs easily, allowing you to create scales that fit your dimensions perfectly.

What Are the Best Printers for This Project?

Look for printers that excel in detail and have a reliable extrusion system. Recommendations include the Prusa i3 MK3 or the Creality Ender 3, both well-regarded in the maker community.